Chemical processing industries frequently encounter the challenge of handling corrosive and aggressive fluids. To protect equipment from damage and ensure the safety of operations, lined check valves are widely used in these environments. In this article, we will explore the advantages of using lined check valves in chemical processing, the types of linings that provide corrosion resistance, and specific applications where these valves excel.

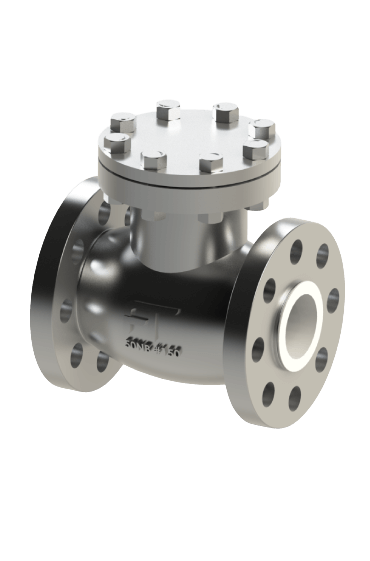

The primary advantage of lined check valves is their ability to prevent backflow while resisting chemical attack. This is particularly important in chemical processing, where fluids often contain harsh chemicals that can corrode unprotected metal valves. Lined check valves provide a barrier between the fluid and the metal by using linings made from materials such as PTFE, PFA, or FEP. These materials are chosen for their chemical inertness, ensuring that the valve does not degrade even when exposed to aggressive substances.

PTFE-lined check valves are commonly used for applications involving acids, alkalis, and solvents, as PTFE offers broad chemical resistance and high temperature tolerance. PFA linings are preferred in applications requiring higher pressure resistance, while FEP is suitable for situations where temperature cycling occurs frequently.

In chemical processing, lined check valves are often installed in pipelines to prevent backflow of hazardous substances. For example, in acid transfer lines, these valves ensure that the corrosive fluid does not flow back into the upstream equipment, thereby protecting the process and minimizing the risk of equipment failure. Additionally, in processes involving multiple chemicals, lined check valves prevent cross-contamination by ensuring one chemical does not flow backward into another processing stream.

The use of lined check valves in chemical processing not only enhances system safety but also extends the life of the equipment by preventing corrosion-related failures.