Corrosion and abrasion are formidable challenges in industries where fluid control is critical. Lined valves have emerged as a robust solution to combat these issues, providing enhanced durability and performance. In this article, we delve into the world of lined valves, exploring their construction, the materials used for lining, and the significant advantages they offer in corrosive or abrasive applications.

I. Understanding Lined Valves

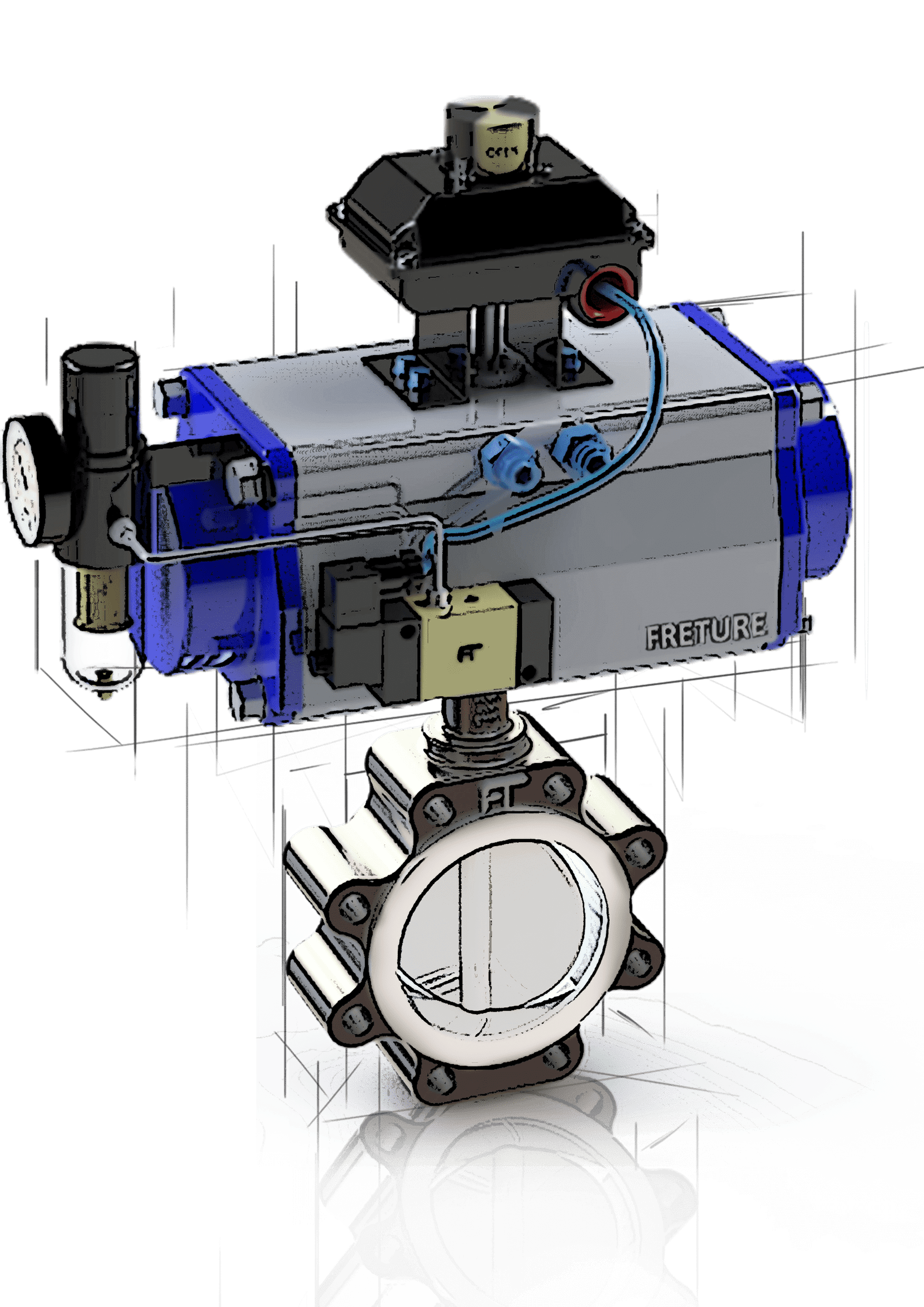

Lined valves are a specialized category of industrial valves designed to withstand aggressive and corrosive environments. The distinguishing feature lies in the protective lining applied to the internal surfaces of the valve. This lining acts as a barrier, shielding the valve from the corrosive effects of the fluid passing through.

|

| Lined Butterfly Valve Manufacturers in Mumbai, India |

II. Construction of Lined Valves

Lining Materials

The choice of lining material is crucial to the success of a lined valve. Common lining materials include PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), FEP (Fluorinated Ethylene Propylene), rubber, and ceramic. Each material has its unique properties, making it suitable for specific applications.

Metallic Shell

Beneath the protective lining, lined valves typically feature a robust metallic shell, ensuring structural integrity and mechanical strength. The metallic shell provides the valve with the necessary support to withstand the pressure and temperature conditions of the application.

Design Considerations

The design of lined valves takes into account the fluid properties, pressure, temperature, and the corrosiveness of the environment. Additionally, the valves are engineered to minimize the risk of lining delamination or damage during operation.

III. Materials Used for Lining

PTFE (Polytetrafluoroethylene)

PTFE is a popular choice for lining due to its exceptional chemical resistance and low friction properties. It is particularly effective in applications involving acids, bases, and corrosive chemicals. PTFE-lined valves are known for their longevity and reliability.

PFA (Perfluoroalkoxy)

PFA shares similarities with PTFE but offers additional advantages such as improved clarity, flexibility, and a higher continuous use temperature. PFA-lined valves are often preferred in applications where transparency and higher temperature resistance are critical.

Rubber Linings

Rubber linings, such as EPDM (Ethylene Propylene Diene Monomer) or Viton, are chosen for their elasticity and resistance to various chemicals. They are commonly used in applications involving abrasive slurries and corrosive fluids.

Ceramic Linings

For extreme abrasion resistance, ceramic linings are employed. Alumina or zirconia ceramics are applied to the valve's internals, providing a durable barrier against abrasive particles present in the fluid.

IV. Advantages in Corrosive or Abrasive Applications

Lifelong Corrosion Resistance

The primary advantage of lined valves lies in their ability to resist corrosion throughout their operational life. This makes them indispensable in industries where aggressive chemical processes are commonplace, ensuring longevity and reducing maintenance costs.

Versatility in Applications

Lined valves find application in a wide range of industries, including chemical processing, petrochemicals, pharmaceuticals, and wastewater treatment. Their versatility makes them suitable for handling various corrosive or abrasive fluids encountered in these sectors.

Enhanced Performance

The protective lining not only shields the valve from corrosion but also contributes to smoother fluid flow. Reduced friction within the valve improves operational efficiency, leading to enhanced performance and energy savings.

V. Conclusion

PTFE, FEP, PFA, Lined valves Manufacturers in Mumbai, India stand as a testament to engineering ingenuity in the face of corrosive and abrasive challenges. By combining robust construction with carefully selected lining materials, these valves provide a reliable solution for industries demanding durability, longevity, and unparalleled resistance to corrosive elements. As technologies continue to advance, lined valves will likely play an increasingly pivotal role in ensuring the integrity and efficiency of fluid control systems across diverse industrial landscapes.

No comments:

Post a Comment