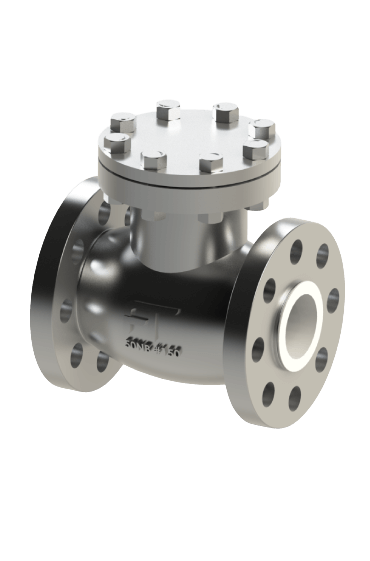

Lined check valves are essential components in various industries, especially where the handling of corrosive or aggressive fluids is common. These valves are designed to prevent backflow while offering enhanced corrosion resistance through the use of internal linings made from materials such as PTFE, PFA, or FEP. In this article, we will discuss how lined check valves provide corrosion resistance, the benefits of different lining materials, and their applications in industries like chemical processing, water treatment, and pharmaceuticals.

In many industrial processes, valves are exposed to corrosive chemicals that can degrade metal components over time. Lined check valves address this issue by incorporating a protective lining inside the valve body, which prevents direct contact between the fluid and the metal. Materials such as PTFE, PFA, and FEP offer excellent chemical resistance, ensuring that the valve remains intact even when exposed to harsh substances.

Each lining material has unique properties. For example, PTFE (Polytetrafluoroethylene) is well-known for its resistance to a wide range of chemicals, including strong acids and bases, and can also withstand high temperatures. PFA (Perfluoroalkoxy alkane) provides similar chemical resistance but with better mechanical strength, making it suitable for high-pressure applications. FEP (Fluorinated ethylene propylene) is highly flexible, offering excellent performance in applications where temperature fluctuations are common.

Typical applications of lined check valves include chemical transfer lines, wastewater treatment systems, and pharmaceutical manufacturing processes where preventing backflow is critical. When selecting a lined check valve, factors such as the fluid's nature, temperature, and pressure must be considered to ensure the appropriate choice of lining material for optimal performance and longevity.

No comments:

Post a Comment