When selecting check valves for industrial applications, it is essential to choose a valve type that meets the specific requirements of the process. Lined check valves, metal check valves, and plastic check valves each offer distinct advantages depending on the operating conditions. In this article, we will compare lined check valves with other types of check valves and discuss when to use them.

|

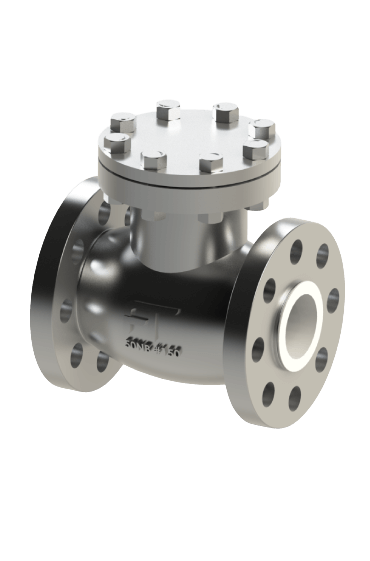

| PFA Lined Check Valve |

Lined check valves are specifically designed for applications involving corrosive fluids, offering enhanced protection through linings made of materials like PTFE, PFA, or FEP. These valves are ideal for chemical processing, water treatment, and pharmaceutical applications where preventing backflow of aggressive substances is crucial. The linings provide a barrier against corrosion, which helps extend the valve's service life.

Metal check valves, made from stainless steel, brass, or other alloys, are commonly used for high-pressure applications where chemical resistance is not a concern. These valves can withstand extreme temperatures and mechanical stress but may not perform well with corrosive fluids. Plastic check valves, such as those made from PVC or polypropylene, are suitable for lower-pressure applications and offer some resistance to chemicals, but they lack the durability and mechanical strength of lined or metal valves.

The choice between these valve types depends on factors such as chemical compatibility, pressure and temperature requirements, and cost considerations. Lined check valves are preferred in scenarios where corrosion resistance is the top priority, while metal or plastic check valves may be more suitable for applications with different requirements.

By understanding the advantages and limitations of each type, industries can make informed decisions to ensure reliable performance and system protection.