Accurate flow control is a fundamental requirement in various industrial processes, especially in applications involving corrosive fluids or stringent safety standards. Lined globe valves are commonly used for their ability to provide precise flow regulation, thanks to their unique design and the chemical-resistant properties of their linings. In this article, we will explore how lined globe valves improve flow control accuracy in industrial systems and discuss their specific applications.

The design of a globe valve, which features a movable plug that seats against a stationary ring, allows for gradual adjustment of flow. This makes globe valves particularly suitable for throttling applications where fine control over flow rates is necessary. The use of linings, such as PTFE or PFA, not only provides chemical resistance but also ensures a smooth internal surface, reducing friction and minimizing fluid turbulence. This helps maintain consistent flow rates, which is essential in applications like chemical dosing, steam regulation, or cooling systems in power plants.

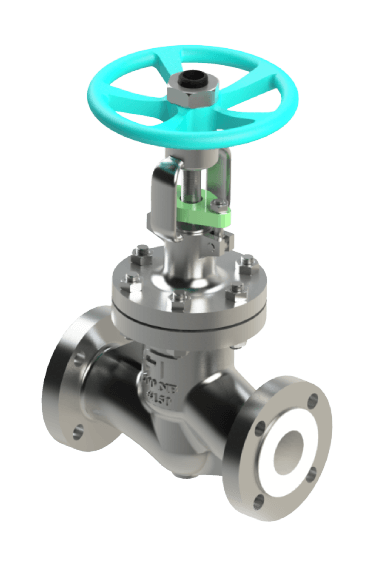

|

| PVDF Lined Globe Valve |

Lined globe valves are also valuable in pharmaceutical manufacturing, where precise flow control is necessary to meet regulatory standards and ensure product quality. In such cases, lined valves help maintain the integrity of the fluid by preventing contamination from metal components, which could occur in unlined valves. The choice of lining material, valve size, and trim design can further optimize flow control accuracy and ensure reliable performance under various operating conditions.

Implementing lined globe valves in industrial systems can lead to more efficient operations, reduced maintenance costs, and compliance with safety and environmental regulations. Proper valve selection and maintenance practices are essential for maximizing the benefits of these versatile flow control devices.