In chemical processing, lined ball valves offer significant benefits due to their corrosion-resistant properties and ability to handle aggressive fluids. These valves feature an internal lining that protects the metal valve body from chemical exposure, making them ideal for environments where corrosive substances are prevalent. This article explores the advantages of using lined ball valves in chemical processing applications.

|

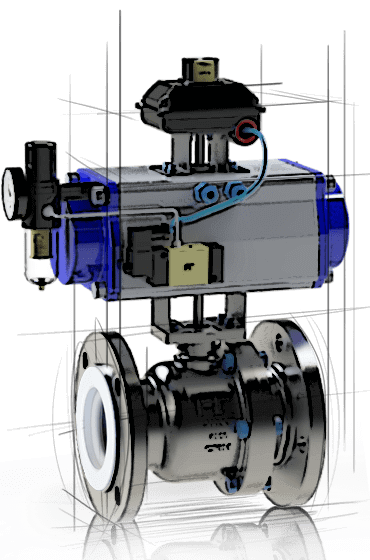

| Lined Ball Valves |

One of the primary benefits of lined ball valves in chemical processing is their ability to handle a wide range of corrosive fluids. The lining materials used, such as PTFE, PFA, or FEP, provide excellent resistance to chemical reactions, ensuring the valve's longevity and reducing the need for maintenance. This capability is especially important in processes involving strong acids, alkalis, and solvents that can quickly corrode standard metal valves.

The smooth interior surface of the lining also helps to maintain consistent fluid flow by minimizing friction, which can be a concern in processes requiring precise control. Lined ball valves are also known for their tight shut-off capabilities, making them suitable for applications where preventing leaks is critical, such as in the handling of hazardous chemicals.

Additionally, PTFE, PFA, FEP lined Ball valves are easy to operate and have a relatively low torque requirement, which can help reduce wear on actuators and improve overall system efficiency. They are suitable for both manual and automated operations, providing flexibility for integration into various chemical processing systems.

No comments:

Post a Comment