Lined ball valves are designed to provide long-term, reliable performance in corrosive environments. However, proper maintenance practices are essential to ensure their longevity and prevent potential failures. This article discusses the best practices for maintaining lined ball valves, including inspection routines, cleaning procedures, and common troubleshooting techniques.

Regular inspections are necessary to detect signs of wear or damage early. The lining should be examined for cracks, blistering, or discoloration, which could indicate chemical permeation. If any issues are detected, the valve should be repaired or replaced to avoid compromising the system's safety and efficiency.

|

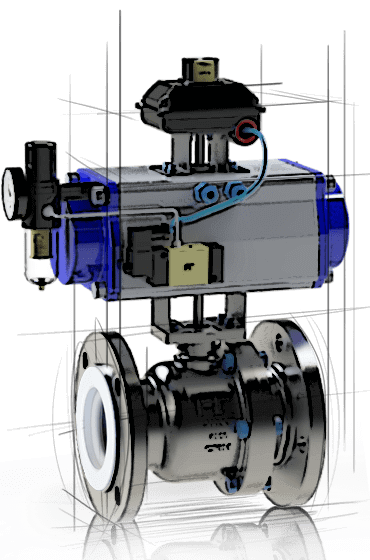

| PTFE, PFA, FEP Lined Ball Valve |

Cleaning lined ball valves should be done carefully to avoid damaging the lining. It is recommended to use non-abrasive cleaning agents and tools. If the valve has been exposed to a particularly aggressive chemical, a compatible cleaning agent should be used to avoid further chemical reactions. For example, certain solvents may damage PTFE linings, so choosing an appropriate cleaning method is crucial.

When it comes to troubleshooting, common issues with lined ball valves include leaks, difficulty in operation, and loss of shut-off capabilities. These problems are often caused by damaged linings, worn-out seats, or debris buildup. Performing routine maintenance, such as flushing the valve and inspecting the seats, can help prevent these issues.

By following best maintenance practices, industries can ensure that their lined ball valves remain operational for extended periods, reducing downtime and maintenance costs.

No comments:

Post a Comment