Industrial fluid handling demands precision, reliability, and resilience. Among the array of valves designed to meet these criteria, the lined gate valve stands as a cornerstone, offering a unique set of advantages that cater to diverse industrial needs.

Understanding PTFE Lined Gate Valves

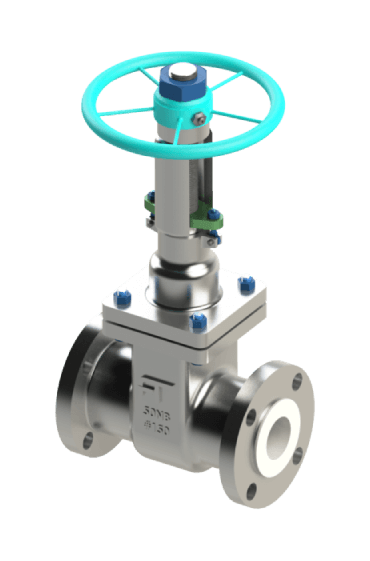

Lined gate valves are a variant of the traditional gate valve, enhanced with linings made from materials like PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), PVDF (Polyvinylidene fluoride), or other corrosion-resistant materials. This innovative design marries the robust functionality of gate valves with the exceptional chemical resistance and durability of these linings.

|

| PTFE Lined Gate Valves |

Unmatched Benefits:

Corrosion Resistance: The primary advantage lies in their ability to withstand corrosive substances, making them ideal for industries dealing with aggressive chemicals.

Zero Leakage: The gate design ensures a tight seal, preventing leakage even in high-pressure applications, enhancing operational safety.

Versatility: These valves adapt seamlessly to various environments, from chemical processing plants to pharmaceutical industries, due to their compatibility with a wide range of fluids.

Durability: The combination of sturdy gate mechanisms and resilient linings results in valves with extended lifespans, reducing maintenance and replacement costs.

Applications Across Industries

- Chemical Processing: Handling corrosive acids, alkalis, and solvents.

- Oil and Gas: Managing abrasive fluids in extraction and refining processes.

- Water Treatment: Ensuring reliability in harsh environments.

Conclusion

Lined gate valves epitomize the marriage between reliability and resilience in industrial fluid handling. Their ability to withstand corrosive substances, maintain tight seals, and adapt to diverse environments positions them as indispensable assets across various sectors.

In an era where operational efficiency and safety take precedence, these valves serve as guardians of seamless operations, providing a robust solution for fluid control in demanding industrial settings. Their versatility, durability, and corrosion resistance continue to make them a staple choice for engineers and industries striving for excellence in fluid management systems.

No comments:

Post a Comment