PFA Ball valves are essential components in industries that handle aggressive chemicals, high temperatures, and demanding operational conditions. These valves are lined with Perfluoroalkoxy (PFA), a high-performance fluoropolymer known for its exceptional chemical resistance, durability, and non-stick properties. Due to their superior performance, PFA-lined ball valves are widely used in industries such as chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing. This article explores the material properties, advantages, applications, selection criteria, and maintenance of these Ball valves.

|

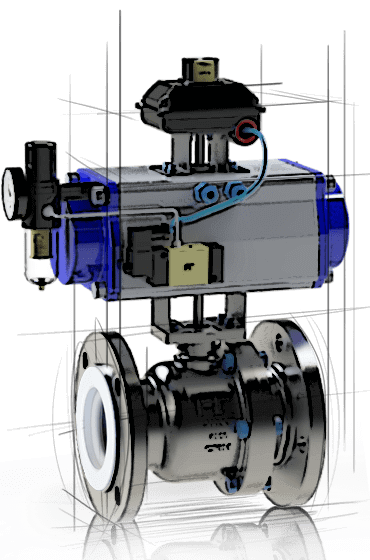

| PFA Lined Ball Valves |

Material and Construction of PFA Ball Valves

PFA is a fluoropolymer with properties similar to PTFE (Polytetrafluoroethylene) but with enhanced thermal and mechanical strength. The lining process involves coating the internal surfaces of the valve body and ball with PFA, creating a smooth, chemically inert barrier that prevents corrosion, contamination, and wear.

Key features of PFA-lined ball valves include:

Superior Chemical Resistance: Suitable for strong acids, alkalis, solvents, and highly corrosive substances.

High Thermal Stability: Withstands temperatures up to 200°C (392°F), making it ideal for extreme environments.

Non-stick Properties: Reduces the risk of material buildup, ensuring consistent flow and performance.

Smooth Surface Finish: Minimizes pressure drops and enhances flow efficiency.

Advantages of PFA Ball Valves

These valves offer several advantages that make them a preferred choice for industries requiring corrosion-resistant and high-performance flow control solutions:

Exceptional Chemical Resistance: These valves can handle highly aggressive chemicals, making them ideal for harsh industrial processes.

Extended Durability: The PFA lining protects the metal body from corrosion, extending the valve's operational lifespan.

Low Maintenance: Their self-lubricating properties reduce wear and tear, minimizing maintenance costs.

Reliable Sealing: Ensures zero-leakage performance, which is crucial for preventing contamination in sensitive processes.

Versatile Applications: Suitable for use in hazardous and high-purity environments, ensuring safety and efficiency.

Applications of PFA Ball Valves

Due to their robust construction and resistance to harsh conditions, These Ball valves are extensively used in various industries, including:

Chemical Processing: Handles highly reactive chemicals, acids, and solvents in manufacturing plants.

Pharmaceutical Industry: Used in processes requiring ultra-pure fluid handling to maintain product integrity.

Food & Beverage Industry: Ensures compliance with hygiene and safety standards for food-grade materials.

Semiconductor Manufacturing: Prevents contamination in high-purity gas and chemical distribution systems.

Selecting the Right PFA Ball Valve

When choosing a PFA-lined ball valve, several factors should be considered to ensure optimal performance and safety:

Chemical Compatibility: Verify that the PFA lining is resistant to the chemicals in your process.

Temperature & Pressure Ratings: Ensure the valve can withstand operational pressures and extreme temperatures without degradation.

End Connection Types: Select from options like flanged, threaded, or welded connections based on system requirements.

Flow Control Requirements: Choose between full bore or reduced bore designs depending on flow rate needs.

Compliance Standards: Ensure the valve meets industry regulations, such as ISO, ANSI, and FDA standards.

Maintenance and Longevity of PFA Ball Valves

Proper maintenance is essential to maximize the lifespan and efficiency of these Ball valves. Here are some best practices:

Regular Inspections: Check for signs of wear, leakage, or chemical degradation.

Proper Cleaning: Use compatible cleaning agents to prevent PFA degradation.

Avoid Mechanical Damage: Handle valves carefully to prevent scratching or damaging the PFA lining.

Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and replacement intervals.

Conclusion

These Ball valves provide a highly reliable and durable solution for industries dealing with aggressive chemicals, high temperatures, and demanding flow conditions. Their chemical resistance, longevity, and low maintenance requirements make them an excellent choice for applications requiring a corrosion-resistant ball valve. When selecting a PFA Lined Ball valve, it is crucial to consider factors such as chemical compatibility, temperature resistance, and industry standards to ensure optimal performance. Investing in high-quality manufacturing ensures better efficiency, safety, and long-term cost savings for industrial operations.