When it comes to industrial flow control, the selection of the right valve can make a critical difference in safety, efficiency, and long-term cost savings. In industries where operations involve corrosive chemicals, aggressive acids, or sensitive processes, conventional metal valves often fall short. This is where Teflon lined valves stand out as a proven solution, offering unmatched chemical resistance, reliability, and durability.

Why Teflon Lining Matters

Unlike traditional metallic valves that corrode or degrade over time, PTFE (Polytetrafluoroethylene) lining provides superior resistance to aggressive chemicals and extreme temperature fluctuations. The Teflon lining creates a protective barrier between the process fluid and the valve body, ensuring consistent performance in even the harshest conditions.

This protection is not just about longevity—it is about safety and compliance. By reducing the risks of leakage, contamination, or hazardous emissions, Teflon lined valves help industries maintain cleaner and safer operations while adhering to strict international standards.

Wide Range of Lined Valves

Teflon lined valves are available in multiple types to cater to diverse industrial requirements:

-

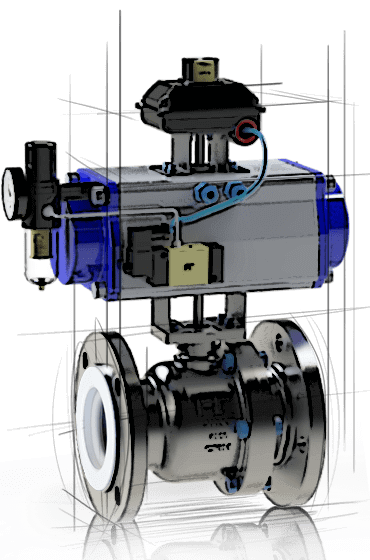

Ball & Butterfly Valves – Ensure efficient flow isolation and smooth operation.

-

Check & Swing Check Valves – Prevent reverse flow, protecting pumps and pipelines.

-

Gate & Globe Valves – Deliver precision control and high durability.

-

Plug Valves – Provide reliable shutoff in demanding chemical processes.

-

Sampling & Sight Glass Valves – Enable safe monitoring and sterile sampling.

-

‘T’ Basket Strainers – Filter out impurities, ensuring protection of downstream systems.

This wide product range allows industries to select the exact valve type suited for their unique applications, ensuring customized performance and greater operational control.

Key Benefits for Industrial Operations

The adoption of Teflon lined valves offers multiple advantages that directly impact performance, safety, and costs:

-

Chemical Compatibility – PTFE-lined valves can handle highly aggressive acids, alkalis, solvents, and corrosive compounds without degradation.

-

Zero Leakage Assurance – Advanced sealing design minimizes leakages, improving safety in sensitive operations.

-

Extended Life Cycle – The corrosion-resistant lining extends service life, reducing downtime and replacement expenses.

-

Operational Efficiency – Smooth internal surfaces enhance flow control and reduce pressure drops, improving productivity.

-

Regulatory Compliance – Designed to meet international safety, quality, and environmental standards.

For industries under pressure to maintain compliance and efficiency while reducing costs, these benefits make lined valves an indispensable choice.

Industry-Specific Importance

Each industry faces unique challenges, and Teflon lined valves provide tailored solutions:

-

Chemical Processing Plants – Rely on lined plug valves and ball valves for handling corrosive applications safely.

-

Pharmaceutical Manufacturing – Uses sight glass and sampling valves to ensure sterile, contamination-free processes.

-

Oil & Gas Facilities – Require lined swing check valves to safeguard high-pressure pipelines against reverse flow.

-

Food & Beverage Industry – Depends on basket strainers to filter out impurities and maintain product integrity.

This versatility demonstrates why lined valves are not just components, but vital enablers of operational excellence across industries.

The Human Side of Valve Selection

Behind every valve installation lies a team of engineers, operators, and maintenance professionals who depend on equipment to perform flawlessly. A leaking or corroded valve can bring entire systems to a halt, compromise worker safety, and lead to costly downtime.

By choosing Teflon lined valves, industries are not only investing in reliable equipment but also protecting people, processes, and products. This human dimension underscores why lined valves are considered critical infrastructure in modern industrial plants.

Conclusion

The importance of Teflon lined valves in today’s industries cannot be overstated. They provide unmatched reliability, chemical resistance, and long-term performance in critical applications where failure is not an option. Whether in chemical, pharmaceutical, oil & gas, or food processing industries, lined valves ensure safety, compliance, and efficiency.

As a trusted name in the field, Freture Techno Pvt. Ltd., a leading manufacturer in India, delivers a complete range of lined valves designed to meet the highest standards of performance and safety. By partnering with Freture, industries can confidently achieve efficiency, regulatory compliance, and long-term operational success.