In the intricate network of fluid management systems across industries, the role of valves is indispensable. Among the diverse array of valves, the lined check valve emerges as a crucial component, contributing significantly to the seamless and efficient operation of fluid handling systems.

Understanding Lined Check Valves

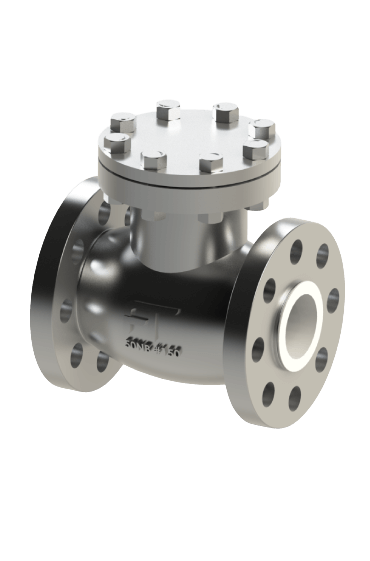

Lined check valves, a pivotal subset of the valve family, are designed to allow fluid to flow in one direction while preventing backflow in the opposite direction. Their construction involves a body lined with materials such as PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), PVDF (Polyvinylidene fluoride), or other corrosion-resistant substances. This lining shields the valve from corrosive substances, ensuring longevity and reliability even in aggressive chemical environments.

|

| PTFE Lined Check Valve Manufacturers in India |

Functionality and Importance

Flow Regulation: Lined check valves maintain consistent flow direction, preventing reverse flow and ensuring system efficiency.

Corrosion Resistance: The lining material's exceptional resistance to corrosive substances preserves the valve's integrity and functionality in harsh operating conditions.

Versatility: These valves find application across diverse industries, from chemical processing plants to pharmaceuticals and water treatment facilities, owing to their adaptability and reliability.

Applications Across Industries

- Chemical Processing: Managing corrosive fluids and chemicals while maintaining system integrity.

- Pharmaceuticals: Ensuring purity and consistency in critical production processes.

- Water Treatment: Preventing backflow and preserving the integrity of treatment systems.

Advantages of Lined Check Valves

Reliability: Ensuring uninterrupted flow while preventing backflow, thereby maintaining system efficiency.

Corrosion Resistance: Withstanding aggressive chemicals and corrosive substances, extending the valve's lifespan and reducing maintenance needs.

Enhanced Safety: Contributing to safer operations by preventing potential system failures caused by backflow.

Conclusion

Lined check valves represent an indispensable asset within fluid handling systems, offering a critical line of defense against backflow and corrosion. Their ability to regulate flow, resist corrosion, and ensure system integrity makes them integral components across a wide spectrum of industries.

In an era where efficiency, safety, and reliability are paramount, the role of lined check valves in safeguarding fluid handling systems cannot be overstated. As industries evolve, these valves continue to play a pivotal role in upholding operational efficiency and safety standards, ensuring the smooth and reliable functioning of fluid management systems worldwide.

No comments:

Post a Comment