Choosing the right lined ball valve for industrial applications involves considering factors such as the type of lining material, valve size, pressure rating, and end connections. In this article, we will discuss the essential factors to consider when selecting a lined ball valve, including the advantages of different lining materials and how to match the valve's features to the intended application.

The type of lining material used in a PTFE, PFA, FEP Lined Ball Valve is one of the most crucial considerations. PTFE is the most popular choice due to its high resistance to a broad range of chemicals, including strong acids, bases, and solvents. It also offers excellent temperature resistance. For applications where higher pressure and mechanical strength are required, PFA-lined valves might be a better choice, as PFA has better mechanical strength while maintaining chemical resistance. FEP-lined valves, on the other hand, are suitable for applications with frequent temperature fluctuations due to their flexibility.

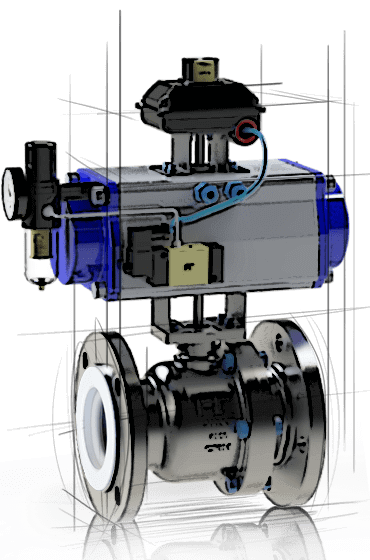

|

| PTFE, PFA, FEP Lined Ball Valve |

Another important factor is the valve size and pressure rating. Larger valves or those used in high-pressure systems may require reinforced linings to prevent deformation. The end connections, such as flanged, threaded, or socket-weld, should also be chosen based on the piping system requirements.

It is also essential to consider the type of fluid being handled, its temperature, and any potential risks associated with chemical permeation. The right selection can help avoid leaks, corrosion, and other issues that may compromise safety and efficiency.

By carefully considering these factors, industries can select the most suitable lined ball valve for their applications, ensuring reliable operation and prolonged service life.

No comments:

Post a Comment