Lined ball valves are specifically designed to handle corrosive fluids in industries such as chemical processing, pharmaceuticals, and water treatment. These valves incorporate a lining material, typically made from PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy alkane), or FEP (Fluorinated ethylene propylene), that acts as a protective barrier against aggressive chemicals. This article explores how lined ball valves are used to handle corrosive fluids and the advantages they offer over traditional metal valves.

PTFE PFA, FEP Lined Ball Valves have a distinct advantage in corrosive fluid applications due to their non-metallic internal surface. The lining materials used are highly resistant to chemical reactions, ensuring that the valve’s integrity remains intact even in harsh environments. PTFE is the most commonly used lining material because of its excellent chemical resistance and ability to withstand high temperatures. PFA and FEP offer similar benefits, but with slightly different mechanical properties; for instance, PFA has better mechanical strength than PTFE, while FEP is more flexible.

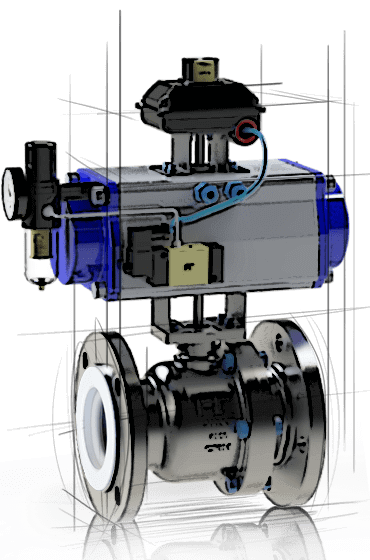

|

| PTFE Lined Ball Valve |

In industrial settings, the transport of corrosive substances like acids, alkalis, and solvents can lead to rapid wear and tear of standard metal valves. Lined ball valves prevent this degradation, significantly extending the valve's lifespan and reducing the need for frequent maintenance. Additionally, their smooth internal surfaces help to minimize fluid friction, ensuring that the flow remains consistent.

Common applications for lined ball valves include chemical injection systems, wastewater treatment facilities, and fluid management in the pharmaceutical industry. These valves are well-suited for shut-off applications and can operate effectively in systems where the fluids are highly corrosive. The choice of lining material depends on the nature of the fluid, temperature, and pressure requirements, making lined ball valves a versatile option for various industries.

No comments:

Post a Comment