Operational safety and efficiency are critical concerns in industrial settings, where the handling of hazardous materials and complex processes is a daily challenge. Lined valves, with their robust construction and corrosion-resistant properties, play a vital role in ensuring both safety and efficiency in various industries. This article explores how lined valves contribute to operational safety, enhance efficiency, and support the overall reliability of industrial systems.

Ensuring Operational Safety

Safety is paramount in industries such as chemical processing, pharmaceuticals, and oil and gas, where the mishandling of hazardous substances can lead to serious accidents and environmental damage. Lined valves enhance operational safety through several key mechanisms:

Corrosion Resistance: One of the primary advantages of lined valves is their resistance to corrosion. Corrosion can weaken valve structures, leading to leaks or failures that pose significant safety risks. Lined valves, with linings made from materials like PTFE, PFA, and ECTFE, provide a durable barrier against corrosive substances, ensuring the integrity of the valve and preventing dangerous leaks.

|

| Lined (PTFE, PFA, FEP) Ball Valve Manufacturer in Mumbai, India |

Containment of Hazardous Substances: Lined valves are designed to contain hazardous chemicals effectively, preventing their escape into the environment. This containment is crucial in industries where the handling of toxic or flammable materials is routine. By securely containing these substances, lined valves minimize the risk of exposure and accidents, protecting both workers and the environment.

Reliability in Extreme Conditions: Many industrial processes involve extreme temperatures and pressures, which can compromise the performance of standard valves. Lined valves are engineered to withstand such conditions, maintaining their functionality and safety even under stress. This reliability reduces the likelihood of valve failure and the associated risks of operational disruptions and safety incidents.

Compliance with Safety Regulations: Lined valves help industries comply with stringent safety regulations set by authorities like OSHA and EPA. Compliance with these regulations is essential for minimizing risks and avoiding costly fines and legal issues. Lined valves support regulatory compliance by providing reliable and safe performance in hazardous applications.

Enhancing Operational Efficiency

In addition to ensuring safety, lined valves contribute significantly to the efficiency of industrial operations. Their design and materials offer several advantages that enhance process efficiency and reduce operational costs:

Reduced Maintenance Needs: The corrosion-resistant properties of lined valves mean they require less frequent maintenance compared to unlined valves. This reduction in maintenance needs translates to lower downtime and fewer interruptions in industrial processes. As a result, industries can maintain higher levels of productivity and efficiency.

Longer Service Life: Lined valves typically have a longer service life due to their durable construction and resistance to wear and tear. This longevity reduces the need for frequent replacements, lowering the overall cost of ownership and contributing to more efficient resource use. Industries can benefit from consistent valve performance over extended periods, enhancing operational stability.

Improved Flow Control: Precise flow control is essential for optimizing industrial processes. Lined valves offer superior control over the flow of fluids and gases, ensuring that processes operate within optimal parameters. This precise control helps in maintaining the quality and consistency of the output, whether in chemical reactions, pharmaceutical manufacturing, or water treatment processes.

Energy Efficiency: Efficient valves can contribute to overall energy savings in industrial operations. By ensuring smooth and reliable flow control, lined valves minimize energy losses associated with leaks, friction, and flow disruptions. This efficiency supports the broader goals of reducing energy consumption and enhancing sustainability in industrial settings.

Supporting System Reliability

The reliability of industrial systems is a key factor in achieving both safety and efficiency. Lined valves play a crucial role in supporting system reliability through their robust design and performance characteristics:

Consistent Performance: Lined valves provide consistent performance even under challenging conditions. This consistency is vital for maintaining the reliability of critical industrial processes, where any deviation can lead to significant issues. Industries can rely on lined valves to deliver stable and predictable results, contributing to overall system reliability.

Minimizing Downtime: Unplanned downtime can be costly and disruptive to industrial operations. Lined valves help minimize downtime by reducing the frequency of maintenance and replacements. Their durability and resistance to corrosion ensure that they remain operational for longer periods, supporting continuous and reliable operations.

Adaptability to Various Applications: Lined valves are adaptable to a wide range of applications and industries. Whether dealing with aggressive chemicals in a chemical plant, maintaining sterility in a pharmaceutical facility, or ensuring the safe flow of water in treatment plants, lined valves provide the necessary reliability and performance. This versatility makes them an essential component in diverse industrial systems.

Enhancing Process Control: The precise control offered by lined valves enhances the reliability of industrial processes. Operators can fine-tune processes to achieve optimal performance, ensuring that systems run smoothly and efficiently. This control is particularly important in applications where precise conditions are necessary for successful outcomes.

Conclusion

Lined valves are indispensable in enhancing operational safety and efficiency in industrial settings. Their corrosion-resistant properties, ability to contain hazardous substances, and reliable performance under extreme conditions make them vital components in maintaining safe and efficient operations. By reducing maintenance needs, extending service life, and improving flow control, lined valves contribute significantly to the overall reliability of industrial systems.

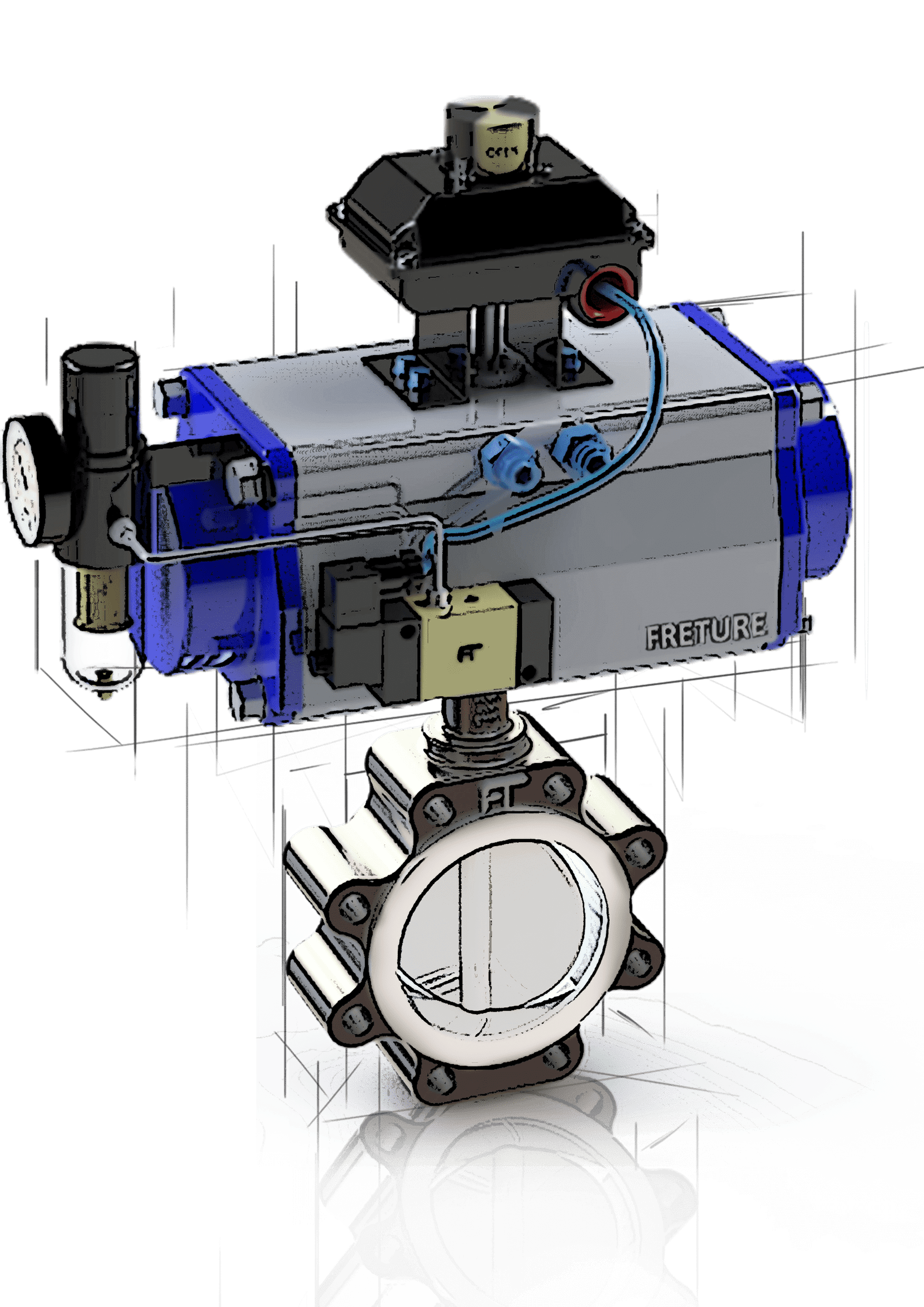

As industries continue to prioritize safety, efficiency, and sustainability, the adoption of advanced lined valve technologies will be essential. Companies like Freture Techno Pvt. Ltd., a leading manufacturer of lined valves in Mumbai, India, are at the forefront of providing high-quality solutions that meet the diverse needs of their clients, ensuring safe and efficient industrial operations.