In the complex tapestry of industrial processes, the demand for corrosion-resistant valves has driven the innovation of lined valves. These valves, fortified with durable linings, play a pivotal role in ensuring the longevity and efficiency of critical systems across various industries. This article delves into the world of lined valves, focusing on three prominent types – lined ball valves, lined butterfly valves, and lined plug valves – and their applications in industries such as chemical processing, oil and gas, and water treatment.

|

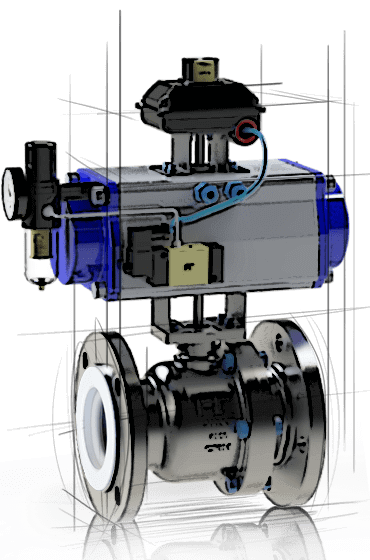

| PTFE Lined Ball Valve |

I. Lined Ball Valves: Precision in Action

Lining Technology Reinventing Reliability

Lined ball valves are a stalwart in the realm of fluid control. Engineered with a lining that shields the valve from corrosive substances, they are the go-to solution in chemical processing plants. The seamless rotation of the ball within the lined cavity ensures precise control over fluid flow. This makes lined ball valves ideal for applications where purity and chemical resistance are paramount.

Applications:

- Chemical processing plants

- Pharmaceutical industries

- Petrochemical refineries

II. Lined Butterfly Valves: A Symphony of Efficiency

Butterfly Valves Redefined

Lined butterfly valves, with their straightforward design and versatile applications, have become indispensable in various industries. The lined disc, which acts as the closure mechanism, minimizes friction and wear. This design, coupled with the corrosion-resistant lining, makes them a reliable choice for industries dealing with aggressive substances.

Applications:

- Water treatment facilities

- Power generation plants

- Chemical manufacturing units

III. Lined Plug Valves: Sealing Excellence

Compact Design, Maximum Reliability

Lined plug valves, known for their compact design and efficient sealing capabilities, find a niche in applications where tight shut-off is crucial. The cylindrical plug, coated with a protective lining, ensures minimal contact with the flowing medium. This feature, coupled with the self-lubricating properties of the lining, makes lined plug valves a preferred choice for critical processes.

Applications:

- Oil and gas pipelines

- Refining and petrochemical plants

- Wastewater treatment facilities

IV. Common Characteristics Across Lined Valves

1. Corrosion Resistance:

All three types of lined valves share a common characteristic – robust corrosion resistance. The linings, often made of materials like PTFE, PFA, or FEP, shield the valves from the deleterious effects of corrosive substances, ensuring longevity and reliability.

2. Temperature and Pressure Resistance:

Lined valves are designed to withstand extreme temperatures and pressures, making them suitable for a wide range of industrial applications. This resilience ensures that the valves maintain optimal performance even in challenging operating conditions.

V. Conclusion: Enhancing Industrial Processes with Lined Valves

In conclusion, the evolution of lined valves has revolutionized fluid control in industries where corrosion poses a significant challenge. Lined ball valves, lined butterfly valves, and lined plug valves each bring their unique attributes to the table, catering to the specific demands of chemical processing, oil and gas, and water treatment.

Choosing the right type of lined valve depends on factors such as the nature of the fluid, operating conditions, and industry requirements. As industries continue to advance, the versatility and reliability of lined valves make them an integral component in ensuring the smooth and efficient operation of critical processes. Embrace the innovation of lined valves and witness the transformation of fluid control in your industrial operations.

No comments:

Post a Comment