Selecting the right lined check valve is crucial for ensuring reliable performance in industrial applications where corrosion resistance is required. With various lining materials, valve designs, and performance specifications available, choosing the appropriate valve can be a complex task. In this article, we will discuss the key considerations for selecting a lined check valve, the benefits of different linings, and how to match these features to the specific requirements of your application.

The first step in choosing a lined check valve is to understand the nature of the fluid being handled. Factors such as chemical composition, temperature, viscosity, and pressure must be considered. For example, PTFE-lined check valves are suitable for handling strong acids, bases, and solvents due to their broad chemical resistance and high-temperature tolerance. PFA linings are ideal for applications that require higher mechanical strength and pressure resistance, while FEP linings offer flexibility and chemical resistance for processes with frequent temperature changes.

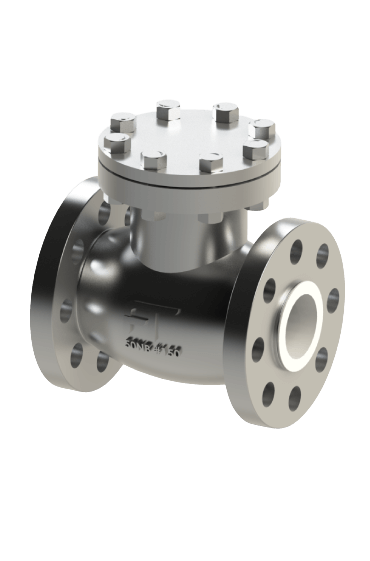

|

| PTFE Lined Checked Valves |

Valve design is another important consideration. For example, swing check valves are often used in applications where low-pressure drop is important, while ball check valves are preferred for handling viscous fluids or slurry because of their ability to prevent clogging.

Additional factors, such as valve size, end connections, and installation space, also influence the choice of lined check valve. It is important to match the valve’s specifications to the system’s requirements to ensure optimal performance and prevent issues such as pressure loss or flow restrictions.

By considering these factors and selecting the right lined check valve, industries can ensure reliable operation and protection against corrosion, reducing maintenance costs and downtime.

No comments:

Post a Comment