While lined check valves are designed to withstand corrosive environments, regular maintenance is essential for ensuring their long-term reliability and performance. In this article, we will discuss best practices for maintaining lined check valves, including inspection techniques, cleaning procedures, and troubleshooting common issues.

Routine inspection is the first step in maintaining lined check valves. Regularly checking for signs of wear or damage to the lining, such as cracks or discoloration, can help detect potential problems early. These signs may indicate chemical permeation, which can compromise the valve's integrity and lead to leaks or backflow. Additionally, the valve's exterior should be checked for any signs of corrosion or damage.

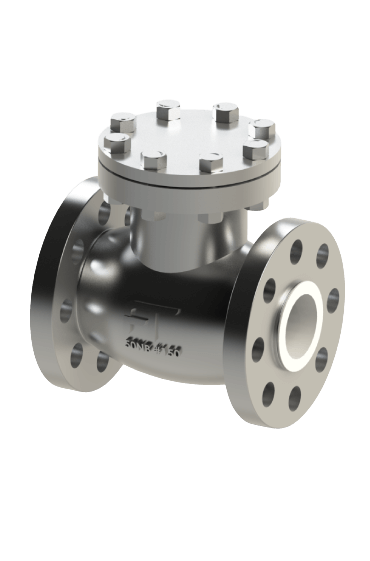

|

| FEP Lined Check Valve |

Proper cleaning of lined check valves is important to prevent buildup of deposits that can affect performance. Non-abrasive cleaning agents and soft brushes should be used to avoid damaging the lining. If chemical cleaning is required, ensure that the cleaning agent is compatible with the lining material to prevent degradation.

If a lined check valve exhibits reduced performance, such as leakage or failure to close properly, troubleshooting should begin by examining the valve's internal components. In some cases, replacing worn-out parts such as the seat or disc may restore functionality. For more severe damage, replacing the entire valve may be necessary.

Implementing a preventive maintenance program that includes routine inspections, cleaning, and testing can help extend the life of lined check valves and reduce unexpected downtime.

No comments:

Post a Comment