Lined globe valves are indispensable components in chemical processing industries, where the handling of aggressive chemicals and corrosive substances is routine. These valves are specifically designed to provide a solution to the challenges posed by corrosive environments by incorporating a lining material inside the valve body. Typically, the lining is made of materials such as PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy alkane), or FEP (Fluorinated ethylene propylene), all of which offer excellent resistance to a wide range of chemicals. In this article, we will explore how lined globe valves enhance corrosion resistance, the benefits associated with various lining materials, and the typical applications of these valves in chemical processing.

The chemical processing industry often involves the transport and control of fluids that can be highly corrosive, including strong acids, bases, and other aggressive substances. Traditional metal valves, even when made from corrosion-resistant alloys, can suffer from gradual degradation due to exposure to these harsh chemicals. Lined globe valves address this problem by providing a protective lining that prevents direct contact between the fluid and the metal valve body. This barrier significantly reduces the risk of corrosion, thus extending the service life of the valve and minimizing the frequency of maintenance.

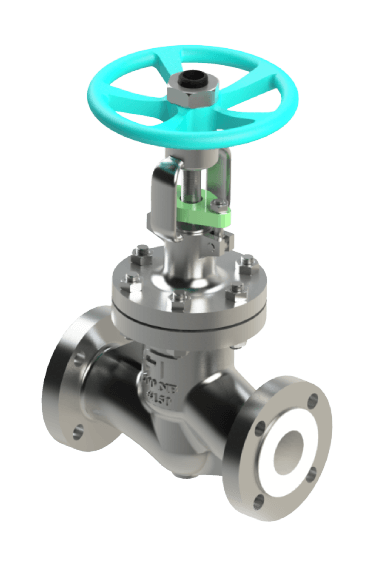

|

| PTFE Lined Globe Valve Manufacturers in India |

The lining materials used in these valves offer different advantages. For example, PTFE is known for its broad chemical resistance and ability to withstand high temperatures, making it suitable for handling strong acids, alkalis, and organic solvents. PFA, while similar to PTFE in terms of chemical resistance, has better mechanical strength and can handle higher pressure applications. FEP offers a combination of flexibility and chemical resistance, which is beneficial in situations where temperature fluctuations are common.

Common applications for lined globe valves in chemical processing include chemical injection systems, acid transfer lines, and fluid handling in petrochemical plants. When selecting a lined globe valve, factors such as the nature of the fluid, temperature, pressure, and potential for chemical permeation must be considered to ensure compatibility and optimal performance.

By incorporating lined globe valves into chemical processing systems, companies can improve the reliability and safety of their operations while reducing costs associated with valve maintenance and replacement.

No comments:

Post a Comment