When it comes to flow control in industrial processes, choosing the right valve type is critical to achieving optimal performance. Lined globe valves, lined ball valves, and butterfly valves each offer distinct advantages, depending on the specific requirements of the application. In this article, we will compare lined globe valves to other valve types, examining their benefits and limitations in various scenarios.

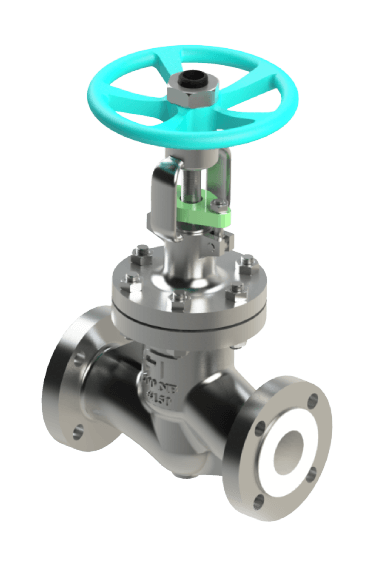

Lined globe valves are designed for applications that require precise flow control, making them ideal for regulating fluid flow in chemical processing, pharmaceutical production, and water treatment. Their design allows for gradual adjustment of flow, which is not possible with lined ball valves, making globe valves suitable for applications where throttling is required. This characteristic makes them valuable in scenarios where exact flow regulation is crucial, such as in chemical dosing systems.

|

| PTFE Lined Globe Valve |

Lined ball valves, while easier to operate and generally requiring lower torque, are better suited for applications that involve frequent full open or closed positions, such as shutoff operations. Their design minimizes pressure drops and can handle larger flow volumes with ease. However, they are not recommended for throttling purposes due to the risk of seat damage from partial opening.

Butterfly valves, on the other hand, are typically lighter and more compact, making them ideal for large-diameter pipelines. They are also cost-effective compared to globe valves for applications that do not require precise flow regulation. However, butterfly valves may not offer the same level of chemical resistance and flow control accuracy as lined globe valves.

The decision between these valve types should consider factors such as flow control needs, operating conditions, chemical compatibility, and budget. Each valve type serves different industrial requirements, and selecting the appropriate valve ensures efficient and safe operation.

No comments:

Post a Comment