Maintaining lined globe valves is essential for ensuring their reliability and extending their operational lifespan. Even though lined valves are designed to withstand corrosion, regular maintenance practices can help prevent valve-related issues and ensure continuous operation. In this article, we will discuss the best practices for maintaining lined globe valves, the common challenges encountered during maintenance, and troubleshooting techniques.

Routine inspections are crucial for the early detection of potential problems. Regular visual checks should be conducted to identify any signs of wear or damage to the lining, such as cracks, blistering, or discoloration. These symptoms could indicate chemical permeation, which can compromise the integrity of the valve. Additionally, any buildup of deposits, such as scale or sediment, should be removed to avoid obstruction of the flow path.

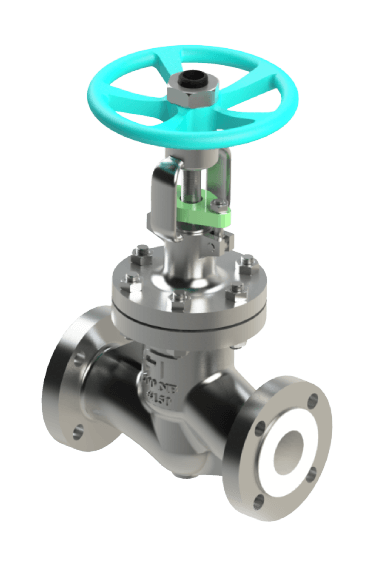

|

| PVDF Lined Globe Valve Suppliers in India |

Proper cleaning techniques are essential for lined globe valves, as abrasive cleaning methods can damage the lining. It is recommended to use mild cleaning agents and non-abrasive tools. If chemical cleaning is required, the cleaning agent should be compatible with the lining material to avoid degradation.

Maintenance should also involve regular testing for valve functionality, ensuring that the valve can be opened and closed smoothly without excessive torque. Over time, linings and seats may need replacement due to wear and tear. When performing repairs, it is important to use the correct replacement materials to maintain chemical resistance and performance standards.

Implementing a preventive maintenance program can help reduce unexpected downtime, extend the service life of lined globe valves, and ensure consistent performance across industrial applications.

No comments:

Post a Comment