Selecting the right lined globe valve for industrial applications requires an understanding of the different materials used for the linings, as well as the valve design and specific operating conditions. Lined globe valves come with various linings, such as PTFE, PFA, and FEP, each offering unique properties that suit different environments and process requirements. In this article, we will discuss the considerations for choosing the right lined globe valve, the benefits of different linings, and how to match these features with the intended applications.

PTFE-lined globe valves are commonly used because of their excellent chemical resistance, high-temperature tolerance, and low coefficient of friction. These properties make PTFE linings suitable for handling aggressive chemicals like concentrated acids, alkalis, and organic solvents. However, for applications where higher pressure and mechanical strength are required, PFA linings may be the better choice. PFA retains the chemical resistance of PTFE but offers superior mechanical properties, which enable the valve to perform well under more demanding conditions.

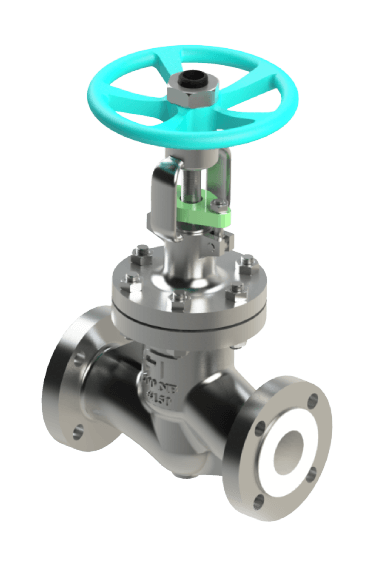

|

| FEP Lined Globe Valve Manufacturers in India |

On the other hand, FEP linings provide a balance of flexibility and chemical resistance, making them appropriate for applications where the process involves frequent temperature changes. For instance, in pharmaceutical manufacturing or food processing, where different stages of production may involve varying temperatures, FEP-lined valves can help maintain consistent performance.

The selection process also involves considering factors such as valve size, pressure rating, temperature range, and end connections to match the valve to the system’s requirements. Additionally, it is crucial to understand the nature of the fluid being handled—its chemical composition, viscosity, and potential for creating sediment. Each of these factors influences the choice of lining material and valve configuration.

By carefully selecting the appropriate lined globe valve, industries can ensure efficient and safe operation while minimizing downtime due to valve failure or chemical incompatibility.

No comments:

Post a Comment