In the realm of industrial fluid handling, the significance of valves can't be overstated. Within this landscape, PVDF (Polyvinylidene fluoride) lined valves emerge as a beacon of durability, reliability, and efficiency. These valves, distinguished by their exceptional resistance to corrosive chemicals and extreme temperatures, have revolutionized various sectors including chemical processing, pharmaceuticals, water treatment, and more.

Understanding PVDF Lined Valves

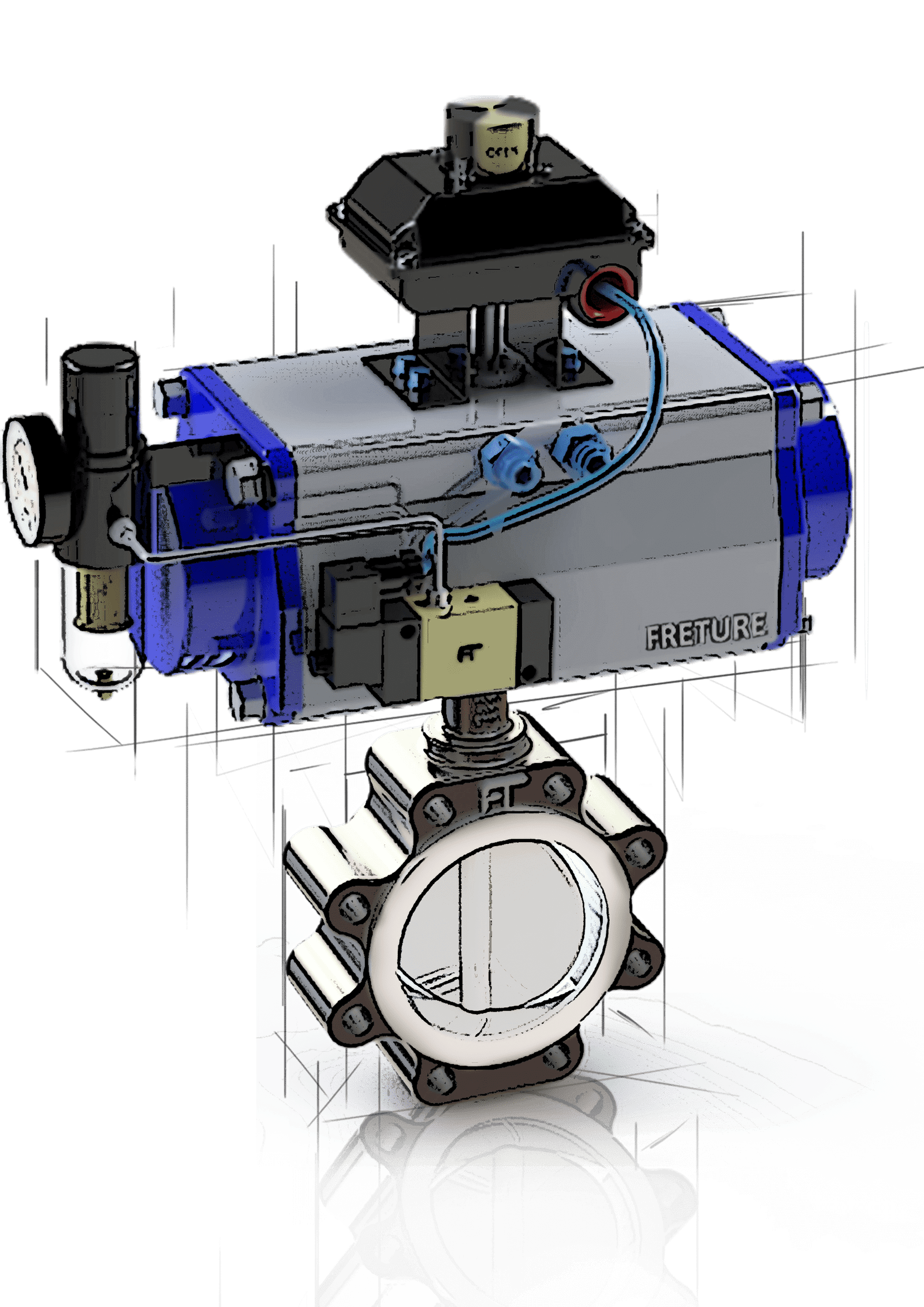

PVDF, a high-performance thermoplastic polymer, exhibits remarkable characteristics that make it an ideal material for lining valves. Its outstanding chemical resistance spans a wide spectrum, encompassing aggressive acids, solvents, and halogens. This attribute ensures the valves' longevity even when handling highly corrosive substances.

|

| PTFE, PVDF, FEP, PFA Lined Valves |

Moreover, PVDF's thermal stability allows these valves to operate seamlessly in environments with temperatures ranging from sub-zero to high heat, ensuring consistent performance across diverse industrial settings.

Unparalleled Benefits

Corrosion Resistance: The primary advantage of PVDF lined valves lies in their ability to withstand corrosive elements. This resistance ensures prolonged functionality, reducing maintenance and replacement costs.

Temperature Stability: Industries dealing with extreme temperatures benefit immensely from PVDF valves, as they maintain structural integrity and functionality under varying heat conditions.

Chemical Compatibility: Versatility is a hallmark of PVDF lined valves. They accommodate a broad range of chemicals, making them invaluable in sectors requiring stringent material compatibility.

Longevity and Reliability: The durable nature of PVDF ensures these valves have an extended lifespan, delivering reliable service over prolonged periods, thereby enhancing operational efficiency.

Applications Across Industries

From chemical processing plants necessitating robust corrosion-resistant valves to water treatment facilities demanding superior chemical compatibility, PVDF lined valves find their application in diverse sectors:

- Chemical Processing: Handling aggressive chemicals and acids.

- Pharmaceuticals: Maintaining purity and integrity during production.

- Water Treatment: Resisting corrosion in harsh environments.

- Petrochemicals: Ensuring safety and efficiency in handling volatile substances.

Conclusion

PVDF lined valves Manufactures in Mumbai, India stand as a testament to technological advancement in material sciences, offering a reliable solution to industries grappling with corrosive substances and extreme operating conditions. Their resilience, chemical compatibility, and longevity make them an indispensable asset, ensuring seamless operations and enhanced safety standards across various industrial domains.

In a world where efficiency and safety are paramount, PVDF lined valves emerge as a beacon of reliability, empowering industries to navigate challenging environments while upholding operational excellence.