In industries where corrosive substances are frequently handled, the use of reliable storage and reaction vessels becomes critical. PTFE (Polytetrafluoroethylene) lined tanks and vessels have been widely adopted due to their outstanding chemical resistance and durability. Their non-reactive and non-stick surface makes them ideal for storing and processing aggressive chemicals. In the chemical processing sector, where material integrity and safety are non-negotiable, PTFE lined equipment has been preferred for ensuring long-term operational reliability.

Understanding PTFE Lined Tanks and Vessels

PTFE, commonly known by its trade name Teflon, is a synthetic fluoropolymer known for its remarkable resistance to chemicals, high temperatures, and thermal degradation. When used as a lining inside tanks and vessels, PTFE forms an inert barrier between the tank wall and the processed media. This not only prevents corrosion but also avoids contamination, enhancing the purity of the stored chemicals.

These tanks are generally fabricated using carbon steel or stainless steel shells, which are internally lined with a uniform layer of PTFE sheets or coatings. The lining is bonded securely using advanced techniques to ensure high adhesion and leak-proof performance under a wide range of operating conditions.

Applications in the Chemical Processing Industry

The chemical processing industry relies heavily on PTFE lined tanks for storing and handling a variety of aggressive chemicals, including acids, alkalis, solvents, and oxidizing agents. Their application is commonly seen in:

-

Acid storage units

Concentrated sulfuric, hydrochloric, and nitric acids can be stored safely without corroding the tank material. -

Reaction vessels

Chemical reactors lined with PTFE enable safe mixing and reaction of reactive compounds under elevated temperatures and pressures. -

Day tanks and feed tanks

Intermediate holding tanks for raw materials and chemical additives benefit from the non-stick, easy-to-clean PTFE surface. -

Scrubbers and absorbers

Gas scrubbing units, where corrosive gases like chlorine or SO₂ are absorbed in liquid media, are typically lined to prevent degradation of the equipment.

Key Advantages in Chemical Processing

The chemical industry operates in an environment where even minor equipment failures can result in hazardous spills, downtime, or loss of product. PTFE lined vessels offer numerous benefits:

-

Corrosion resistance: A chemically inert lining prevents degradation from harsh acids, bases, and solvents.

-

Thermal stability: PTFE maintains its integrity across a broad temperature range, ensuring consistent performance in both hot and cold processes.

-

Product purity: As PTFE does not react with most substances, it prevents product contamination, which is crucial for specialty and fine chemical manufacturing.

-

Reduced maintenance: Unlike unlined metal tanks, PTFE lined tanks require minimal upkeep, reducing long-term operational costs.

Design and Customization

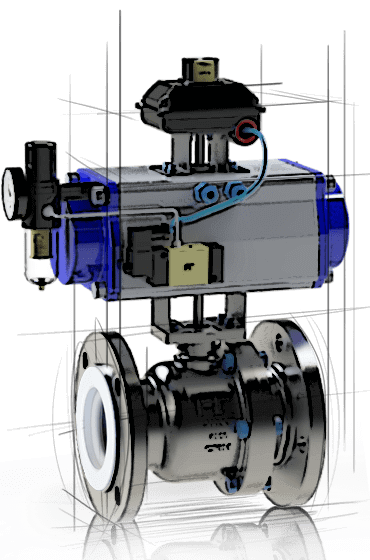

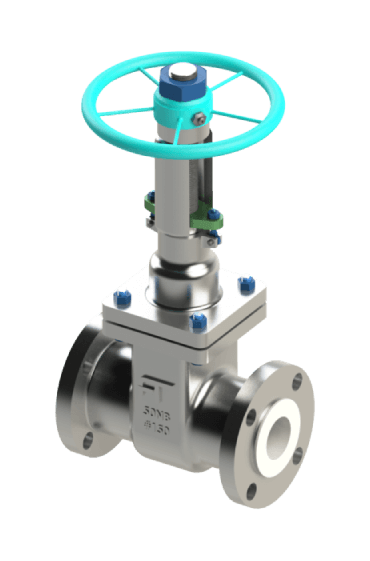

PTFE lined tanks and vessels are available in a variety of sizes and designs, including vertical and horizontal orientations, jacketed configurations, and with specialized fittings like manways, nozzles, and agitators. They can be custom-engineered to match the chemical compatibility requirements and pressure/temperature ratings of specific process lines.

Conclusion

To handle corrosive and high-purity materials in chemical processing plants, PTFE lined tanks and vessels have been increasingly adopted for their superior resistance, operational safety, and longevity. By eliminating the risks associated with corrosion and contamination, these vessels contribute significantly to plant safety, product quality, and cost-effective operations.

For businesses looking to invest in reliable PTFE lined tank solutions, it is recommended to source from experienced PTFE lined tank manufacturers and industrial vessel suppliers who specialize in customized chemical processing equipment.