In highly corrosive and aggressive fluid-handling environments, the integrity of a valve plays a critical role in maintaining safety, efficiency, and long-term performance. Among the many valve solutions available, PTFE lined ball valves have emerged as a trusted choice for industries such as chemical processing, pharmaceuticals, and wastewater treatment, where resistance to harsh chemicals is non-negotiable.

These valves combine the strength of metal bodies with the chemical inertness of PTFE (Polytetrafluoroethylene), commonly known by the brand name Teflon. As a result, they provide a dual advantage—mechanical durability and exceptional chemical resistance. Whether it's acids, bases, or aggressive solvents, PTFE lined ball valves can handle it all without compromising safety or performance.

Why Choose?

PTFE, known for its non-stick and anti-corrosive properties, is an ideal lining material for valves used in chemical industries. When integrated into a ball valve, it creates a seamless internal barrier that prevents the process fluid from contacting the metal surfaces of the valve. This feature significantly extends the service life of the valve and eliminates risks associated with metal corrosion or contamination.

These valves are engineered for on/off flow control and are particularly effective in applications requiring minimal leakage, smooth operation, and frequent actuation. A PTFE ball valve seat ensures tight shut-off and low friction, further enhancing performance.

Key Applications

-

Chemical Processing Plants – Ideal for handling acids, caustics, and solvents.

-

Pharmaceutical Manufacturing – Ensures hygienic flow and resistance to contamination.

-

Food & Beverage Industry – Suitable for corrosive cleaning agents and consistent flow control.

-

Water and Wastewater Treatment – Effective in managing chemically treated water.

-

Pulp and Paper Industry – Used for handling bleaching chemicals and corrosive liquids.

These valves are often used in conjunction with lined ball valves, such as PTFE lined butterfly valves, for complete system protection.

Exploring Valve Types and Features

While PTFE lined ball valves are versatile, specific variations have been developed for different operational needs:

-

PTFE Lined Ball Check Valve: Offers backflow prevention with a corrosion-resistant design.

-

PFA Lined Ball Valve: Similar to PTFE but offers improved high-temperature performance and stress cracking resistance.

-

PTFE Coated Ball Valve: Used where full lining may not be required but chemical protection is still necessary.

Each of these variants is designed to address industry-specific challenges while maintaining the core benefits of chemical resistance, minimal maintenance, and durability.

Manufacturing Standards and Material Quality

Top manufacturers ensure their valves meet global standards such as ANSI, DIN, and ISO. The body materials often include cast iron, ductile iron, or stainless steel, while the lining materials—PTFE or PFA—are selected based on fluid compatibility and temperature/pressure requirements.

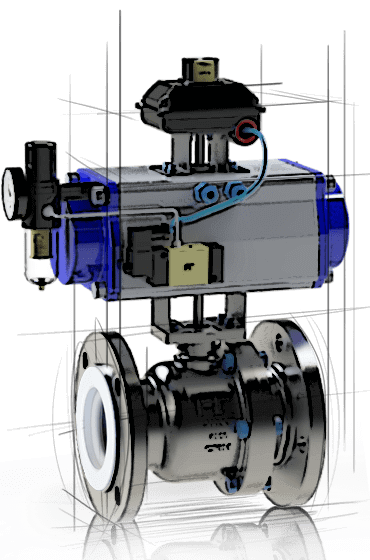

At the heart of their design, PTFE ball valves utilize precision-engineered components, such as anti-blowout stems, low-torque operation, and anti-static features, all contributing to a safer and more reliable valve solution.

Why Source from a Trusted Manufacturer?

When sourcing PTFE-lined valves, ensuring product quality and operational reliability is essential. A reputed PTFE Lined Ball Valve Manufacturer in Mumbai, Freture Techno Pvt. Ltd. delivers superior engineering, premium-grade materials, and consistent performance that align with global standards. The company leverages advanced manufacturing technologies and stringent quality control processes to meet the exacting demands of industrial applications.

In addition to PTFE-lined ball valves, Freture Techno offers a comprehensive range of corrosion-resistant solutions, including PTFE lined butterfly valves and customized configurations tailored to specific process requirements.

Ideal for use in chemical processing, water treatment, and pharmaceutical manufacturing, these valves are designed to withstand aggressive media while delivering reliable, leak-free operation. Available in multiple variants such as PTFE coated ball valves, they combine durability, precision, and long-term performance.

For dependable and high-performance flow control solutions, Freture Techno Pvt. Ltd. stands out as a leading Ball Valve Manufacturer in Mumbai, trusted by industries across India and beyond.