In industrial environments where the use of corrosive chemicals is common, valve materials must be able to resist aggressive substances to ensure long-term durability and reliability. PTFE lined ball valves offer an excellent solution to this challenge by combining the durability of metal valves with the chemical resistance of PTFE (Polytetrafluoroethylene) linings. These valves are widely used in industries like chemical processing, pharmaceuticals, and petrochemicals, where dealing with corrosive or abrasive materials is a daily occurrence.

What is a PTFE Lined Ball Valve?

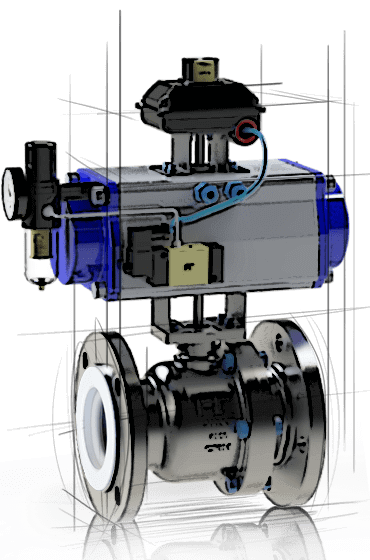

A PTFE lined ball valve is similar to a conventional ball valve but with an inner lining of PTFE, a polymer known for its exceptional resistance to chemicals and extreme temperatures. The ball inside the valve is also coated with PTFE, making the valve ideal for handling corrosive substances that would otherwise damage metal components. This unique construction allows for longer operational life, reduced maintenance costs, and improved safety in processes involving hazardous chemicals.

|

| PTFE, PFA, FEP Lined Ball Valves |

- Corrosion Resistance: The PTFE lining provides outstanding protection against corrosive chemicals, including acids, alkalis, and solvents, making these valves suitable for demanding applications in chemical plants and refineries.

- High Temperature Tolerance: PTFE lined ball valves can withstand extreme temperatures ranging from -50°C to 200°C, offering flexibility in a variety of industrial applications.

- Smooth Flow Control: The smooth, non-stick surface of PTFE allows for excellent flow control and prevents materials from adhering to the valve, reducing the risk of blockages and ensuring consistent performance.

- Low Maintenance: Thanks to the chemical resistance of PTFE, these valves require less maintenance over time, contributing to overall operational efficiency and cost savings.

Applications of PTFE Lined Ball Valves

- Chemical Processing: PTFE lined ball valves are commonly used in chemical plants to handle aggressive chemicals like sulfuric acid, hydrochloric acid, and chlorine. Their corrosion resistance ensures safe and reliable operation in these demanding environments.

- Pharmaceutical Industry: In pharmaceutical manufacturing, where high purity and contamination control are crucial, PTFE lined valves play a vital role in preventing any contamination of sensitive fluids or chemicals.

- Water Treatment: The durability and chemical resistance of PTFE lined ball valves make them ideal for water treatment processes that involve harsh chemicals like chlorine and sodium hydroxide.

- Petrochemicals: Refineries and petrochemical plants frequently use PTFE lined ball valves to manage corrosive byproducts and high-temperature fluids in various processing units.

Conclusion

The use of PTFE lined ball valves in industrial applications provides several key benefits, from enhanced durability to improved safety when handling hazardous chemicals. Industries that demand reliable, long-lasting valve solutions for corrosive environments will find PTFE lined ball valves to be an ideal choice. These valves offer smooth operation, reduced maintenance, and extended service life, making them a cost-effective and efficient solution for critical industrial processes.

No comments:

Post a Comment