Lined gate valves are integral components in many industrial systems, particularly in applications where handling corrosive or abrasive fluids is a regular occurrence. These valves combine the functionality of standard gate valves with enhanced resistance to corrosion, thanks to internal linings made of materials such as PTFE, PFA, or FEP. In this article, we will discuss the key benefits of lined gate valves, explore their applications across various industries, and highlight why they are preferred over unlined alternatives in challenging environments.

|

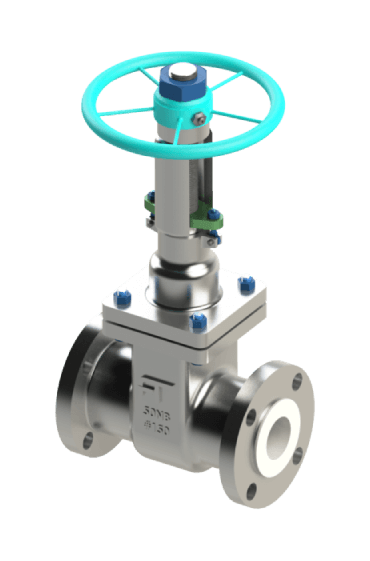

| PTFE Lined Gate Valves |

What Are Lined Gate Valves?

A lined gate valve is a type of gate valve that has an internal lining to protect the valve body and internal components from exposure to harsh chemicals or abrasive materials. The lining acts as a barrier between the valve's metal body and the fluid being controlled, preventing direct contact and thus reducing the risk of corrosion. Common lining materials include PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy alkane), and FEP (Fluorinated ethylene propylene), each of which offers unique benefits in terms of chemical resistance, temperature tolerance, and mechanical strength.

Key Benefits of Lined Gate Valves

Corrosion Resistance: The primary advantage of using lined gate valves is their ability to resist corrosion. In applications involving aggressive chemicals, acids, or solvents, unlined metal valves can deteriorate rapidly, leading to leakage, equipment failure, and costly repairs. Lined gate valves, on the other hand, offer long-term durability and reduced maintenance needs.

Improved Safety: In industries such as chemical processing and pharmaceuticals, handling hazardous substances requires equipment that minimizes the risk of leaks and contamination. Lined gate valves provide a safe solution by creating a reliable seal that prevents harmful chemicals from escaping.

Wide Range of Applications: Lined gate valves are suitable for use in various applications, including chemical processing, water treatment, oil and gas, and pharmaceutical production. Their versatility makes them a preferred choice for processes involving corrosive fluids, high-purity systems, and slurry handling.

Low Maintenance Costs: The use of a lining reduces wear and tear on the valve components, resulting in fewer maintenance requirements and extended service life. This leads to cost savings over the valve's lifespan, making lined gate valves a more economical choice in the long run.

Reduced Downtime: Because lined gate valves are less susceptible to corrosion and wear, they experience fewer failures, which in turn minimizes the risk of unplanned shutdowns. This increased reliability contributes to more consistent operational performance and higher productivity.

Applications of Lined Gate Valves

Chemical Processing: In chemical plants, lined gate valves are essential for handling aggressive substances such as acids, alkalis, and solvents. The chemical resistance provided by the lining ensures that the valves remain operational even in highly corrosive environments, reducing the risk of leaks and process disruptions.

Pharmaceutical Industry: In the pharmaceutical sector, lined gate valves are used in processes requiring high levels of purity and cleanliness. The linings prevent contamination from metallic components, ensuring that the production of drugs and medical products meets strict regulatory standards.

Water and Wastewater Treatment: Lined gate valves are commonly used in water treatment facilities to control the flow of chemicals used for disinfection and pH adjustment. They are also used in wastewater treatment plants to handle abrasive slurries and prevent the buildup of scale and deposits.

Oil and Gas: Although lined gate valves are not typically used for high-pressure applications in the oil and gas industry, they are useful for handling chemicals such as corrosion inhibitors, biocides, and acids during pipeline maintenance and treatment processes.

Food and Beverage Industry: In food processing, lined gate valves are used to handle cleaning chemicals and other aggressive substances without contaminating the food products. The use of FDA-approved lining materials ensures compliance with food safety regulations.

Conclusion

Lined gate valves offer significant advantages in terms of corrosion resistance, safety, and versatility, making them indispensable in industries that deal with aggressive chemicals and abrasive materials. By preventing direct contact between the valve body and the fluid, lined gate valves extend the lifespan of the equipment and reduce maintenance costs. As a result, they are often the preferred choice for critical applications where reliability and safety are of paramount importance.

No comments:

Post a Comment