Choosing the right lined gate valve for your application goes beyond selecting the valve type; it also involves picking the appropriate lining material to ensure reliable performance and longevity. In this article, we will explore different lining materials, such as PTFE, PFA, and FEP, and discuss how to choose the right one based on your specific requirements, including fluid characteristics, temperature, pressure, and mechanical strength.

|

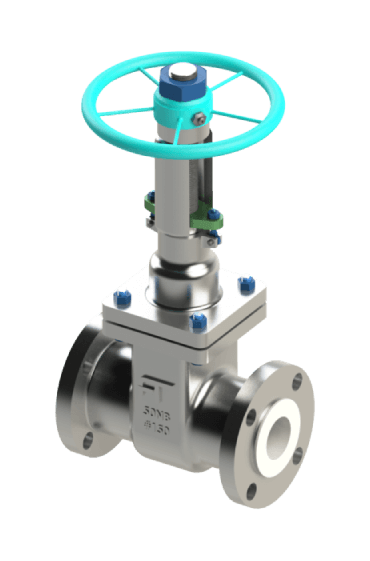

| PFA Lined Gate Valve Manufacturers in India |

Understanding Lining Materials

Lined gate valves are equipped with a lining that acts as a protective barrier between the valve's metallic body and the fluid. The most common lining materials include:

PTFE (Polytetrafluoroethylene): Known for its broad chemical resistance, PTFE is effective against acids, alkalis, and organic solvents. It is also able to withstand high temperatures, typically up to 260°C. PTFE-lined valves are suitable for handling a wide range of fluids, including highly corrosive chemicals.

PFA (Perfluoroalkoxy alkane): PFA offers similar chemical resistance to PTFE but has better mechanical strength and higher resistance to cracking under stress. This makes PFA an ideal choice for applications where the valve may experience frequent temperature fluctuations or mechanical shocks.

FEP (Fluorinated Ethylene Propylene): FEP-lined gate valves provide good chemical resistance but with greater flexibility than PTFE or PFA. They are suitable for lower temperature applications and processes involving temperature cycling.

PVDF (Polyvinylidene Fluoride): PVDF has excellent chemical resistance and mechanical strength, making it suitable for higher-pressure applications. It is often used in processes where mechanical durability is a priority.

Rubber Lining: For abrasive applications, rubber-lined gate valves may be preferred to prevent damage from solid particles. They are commonly used in slurry handling and mining applications.

Factors to Consider When Selecting a Lining Material

Chemical Compatibility: The nature of the fluid being handled is the primary consideration when selecting a lining material. Some materials are better suited for acidic environments, while others may perform well with solvents or alkalis. Always verify the chemical compatibility of the lining with the fluid to avoid degradation.

Temperature Range: The operating temperature of the process should be taken into account. While PTFE and PFA can handle higher temperatures, materials like FEP may be limited to lower temperatures. Selecting a lining material that can withstand the temperature conditions ensures long-term performance.

Pressure Requirements: Higher pressure applications may require more mechanically robust lining materials such as PFA or PVDF. These materials are less likely to deform or crack under pressure compared to softer linings like rubber.

Abrasiveness of the Fluid: For applications involving abrasive materials, such as slurry or solid-laden fluids, rubber-lined or hard-coated linings may be more suitable. These materials can withstand the wear and tear caused by abrasive particles.

Compliance and Certification Requirements: In industries such as pharmaceuticals, food processing, and drinking water treatment, compliance with regulatory standards (e.g., FDA, USP) is crucial. Ensure the lining material used meets the necessary certifications for the application.

Conclusion

Selecting the right lining material for lined gate valves is crucial for ensuring optimal performance and longevity in corrosive or demanding environments. By considering factors such as chemical compatibility, temperature, pressure, and abrasiveness, industries can choose the most suitable lining material for their specific needs.

No comments:

Post a Comment