When selecting valves for handling corrosive fluids, industries often have various options to choose from, including lined gate valves, lined ball valves, and lined butterfly valves. Each valve type has its own advantages and limitations, depending on the specific application requirements. This article compares lined gate valves with other lined valve types, exploring their features, benefits, and drawbacks to help determine which valve is better suited for corrosive fluid applications.

Lined Gate Valves vs. Lined Ball Valves

Flow Control: Lined gate valves are designed for full open or full close positions, making them ideal for applications where on/off control is needed. Lined ball valves, on the other hand, offer better throttling capabilities, allowing for precise flow control.

Sealing Performance: Both lined gate valves and lined ball valves provide excellent sealing capabilities, but lined ball valves generally offer tighter shut-off. The ball valve's spherical design ensures a more consistent and reliable seal, especially in high-pressure applications.

Maintenance Requirements: Lined gate valves have fewer moving parts and are generally easier to maintain. Lined ball valves may require more frequent maintenance due to wear on the seats and seals.

Abrasion Resistance: When handling abrasive materials, lined gate valves with appropriate linings may provide better resistance to wear than lined ball valves, which can suffer from seat damage due to abrasive particles.

Lined Gate Valves vs. Lined Butterfly Valves

Pressure and Temperature Ratings: Lined gate valves can typically handle higher pressure and temperature ranges compared to lined butterfly valves, making them suitable for more demanding applications.

Space Requirements: Lined butterfly valves have a more compact design and require less installation space than lined gate valves. This makes them ideal for installations with space constraints.

Flow Characteristics: Lined butterfly valves are designed for applications where throttling control is required, while lined gate valves are better suited for applications requiring full open or closed positions.

Cost Considerations: Lined butterfly valves are often more economical than lined gate valves, especially in larger sizes. However, the choice between the two should also consider the specific application requirements, such as pressure, temperature, and the nature of the corrosive fluid.

|

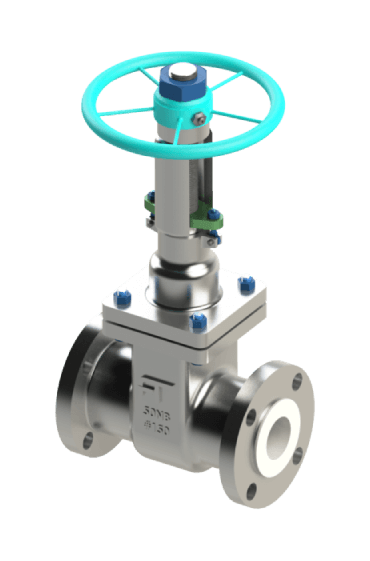

| PVDF Lined Gate Valves |

Choosing the Right Valve Type for Corrosive Fluids

Chemical Compatibility: When handling specific corrosive fluids, it is crucial to select a valve type and lining material that are chemically compatible with the fluid. This ensures the lining will not degrade over time.

Application Requirements: Determine whether the application requires on/off control, throttling, or tight shut-off. Lined gate valves are suitable for on/off control, while lined ball and butterfly valves may be better for applications requiring flow regulation.

System Design and Space Constraints: Consider the layout and available space for valve installation. If space is limited, a lined butterfly valve may be more appropriate.

Budget and Maintenance Considerations: Evaluate the total cost of ownership, including initial purchase price, maintenance requirements, and lifespan. Lined gate valves may offer lower maintenance costs due to their simpler design.

Conclusion

Each type of lined valve—gate, ball, or butterfly—offers distinct benefits for handling corrosive fluids. The choice depends on factors such as flow control requirements, pressure and temperature conditions, space constraints, and budget considerations. Lined gate valves are particularly advantageous for applications requiring reliable on/off control and high-pressure resistance, making them a versatile choice in many industrial settings.

No comments:

Post a Comment