Industrial processes across a variety of sectors often involve the use of corrosive chemicals and high-pressure systems. In such environments, the right valve choice can make a significant difference in ensuring smooth operations and minimizing maintenance costs. PTFE ined butterfly valves offer an effective solution for managing fluid flow in challenging conditions, providing an excellent balance of chemical resistance, durability, and ease of use.

This article will explore the main benefits of PTFE lined butterfly valves, emphasizing their role in enhancing operational efficiency and longevity in industrial settings.

Superior Chemical Resistance

The most notable feature of PTFE (Polytetrafluoroethylene) as a lining material is its superior chemical resistance. When applied to butterfly valves, this property makes them ideal for use in industries that handle aggressive chemicals, acids, alkalis, and solvents. Unlike standard metal valves, PTFE lined butterfly valves can withstand chemical attacks that would typically corrode or degrade unlined valves.

Industries such as pharmaceuticals, petrochemicals, and water treatment benefit significantly from the non-reactive nature of PTFE, ensuring that the process fluids do not cause unwanted reactions or contamination. This leads to safer, more reliable system operations over extended periods.

Long-Lasting Durability

The wear and tear on valves used in harsh environments can lead to frequent replacements, resulting in downtime and increased operational costs. PTFE lined butterfly valves offer a solution to this problem, as PTFE is highly durable and resistant to wear and erosion.

By providing a protective barrier between the valve’s metal body and the process fluids, PTFE ensures that the valve components do not degrade prematurely. This results in longer-lasting valves, which can significantly reduce maintenance and replacement costs over time.

Low Friction and Smooth Operation

One of the key advantages of PTFE lined butterfly valves is their low friction coefficient. PTFE is a naturally slippery material, which means that it allows for smooth valve operation even in the presence of viscous or abrasive fluids. This low-friction characteristic reduces the wear on the valve’s moving parts, extending its operational lifespan.

Additionally, the smooth operation provided by PTFE lined butterfly valves leads to lower energy consumption in automated systems. The ease with which these valves open and close means less power is required, making them more energy-efficient, which is especially beneficial in large-scale industrial applications.

Broad Temperature Range Compatibility

PTFE Lined butterfly valves can function across a wide temperature range, typically from -50°C to 200°C, depending on the specific design. This makes them versatile solutions for applications where temperature extremes are a concern. Whether handling cryogenic fluids or high-temperature steam, PTFE lined valves maintain their integrity, ensuring consistent performance.

In industries like chemical processing or power generation, where fluctuating temperatures are common, this broad temperature range capability makes PTFE lined butterfly valves indispensable.

|

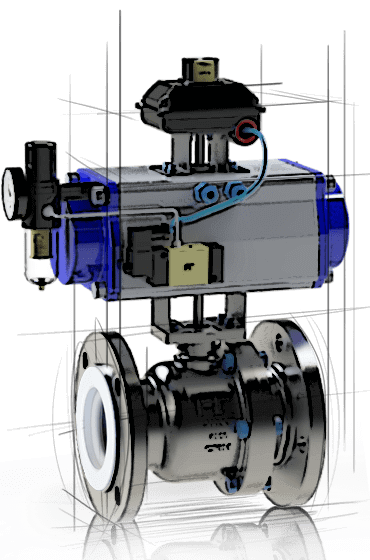

| PTFE, PFA, FEP, PVDF Lined Butterfly Valve manufacturer in Mumbai, India |

Compliance with Hygienic Standards

In industries such as food processing, pharmaceuticals, and biotechnology, maintaining hygienic conditions is critical. PTFE is an FDA-approved material, making it a safe choice for use in applications where product purity must be preserved. The non-reactive nature of PTFE ensures that there is no contamination between the valve and the substances being processed.

PTFE-lined butterfly valves are widely used in food and beverage production lines, pharmaceutical manufacturing, and water purification systems. They help ensure that the products meet the required hygiene and safety standards.

Lightweight and Cost-Effective

Compared to other types of industrial valves, butterfly valves have a relatively simple design, making them lightweight and easy to install. PTFE lined butterfly valves offer an even more cost-effective solution due to their long-lasting performance and minimal maintenance requirements. Their lightweight nature also reduces the strain on piping systems, lowering the risk of wear and tear over time.

The combination of these features makes PTFE lined butterfly valves a practical and affordable choice for businesses looking to optimize their fluid control systems without sacrificing performance or reliability.

The PTFE lined butterfly valve stands out as an efficient, durable, and cost-effective solution for industries that require reliable flow control in challenging environments. Its chemical resistance, low friction operation, temperature versatility, and hygienic compliance make it a valuable asset in industries like pharmaceuticals, food processing, water treatment, and petrochemicals.

Investing in PTFE-lined butterfly valves offers significant advantages, including extended operational life, reduced maintenance costs, and improved safety. With these benefits, it’s no surprise that PTFE lined butterfly valves are becoming the valve of choice for many industries around the world.